How We Weld Hellbender Bandsaw Blades

How We Weld Hellbender Bandsaw Blades

Posted in Maintenance & Care

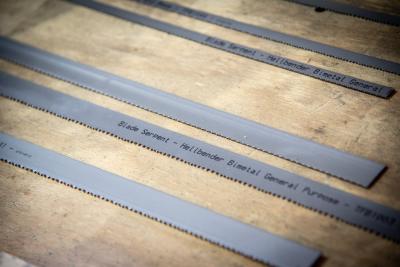

Each Hellbender bandsaw blade is welded to order at our weld center in Tennessee. This is how we weld each blade.

STEP 1

Measured and sheared to length

STEP 2

Welded and annealed using our state-of-the-art blade welders

STEP 3

Weld is rough ground to be flush with blade surface

STEP 4

Teeth in the weld zone are recut

STEP 5

Final grind and polish of the weld

STEP 6

Weld is reannealed

Every weld is tested for bend strength and hardness. At regular intervals, we test tensile strength and perform microscopic weld analysis to ensure we deliver the highest quality welds.

Related Posts

How to Clamp Odd Shapes or Bundles in a Horizontal Bandsaw

04/10/2019| Posted in Maintenance & Care| 7527

Choose the Right Bandsaw Blade for Pipe, Beams, Angles, and Structural Steel

04/12/2019| Posted in Maintenance & Care| 8405

Choosing Coolant To Use For Cutting Metal With Your Bandsaw

04/12/2019| Posted in Maintenance & Care| 22524

What Makes a Good Bimetal Blade: Part 1

04/16/2019| Posted in Maintenance & Care| 4190

Bandsaw Blade Selection for Contour Cutting

05/15/2019| Posted in Maintenance & Care| 8768

How to Fold a Bandsaw Blade (the Right Way)

05/03/2019

Bandsaw Blade Selection for Contour Cutting

05/15/2019

Bandsaw Blade Selection for Contour Cutting

05/15/2019

How to Fold a Bandsaw Blade (the Right Way)

05/03/2019

What Makes a Good Bimetal Blade: Part 1

04/16/2019

Categories

Topics

Tags